System Description

The SLITstream cutting dust removal for slitting units was especially developed to remove the generated dust directly at the knives. The new dust removal extraction hood generates a high air flow within the system directly at the upper knives. This extreme sharp air jet removal also the smallest particles. A blower will be mounted via a pipe system directly with the extraction hoods for each knife. A test filter can be installed to observe the efficiency of the system. After a knife change, the hood is positioned automatically. Not used knife blades are protected completely by the hood. No safety issues due to this feature during web treading.

Electrostatic discharge

In many cases electrostatic charge present on the substrate surface is a major factor in increasing contamination and makes particle removal more difficult. This is why our static control system is always installed prior to the cleaning process to guarantee a neutralised substrate surface and therefore facilitate easier removal of all particles.

For more information follow the this link: Know-how - Dust Removal

Technology

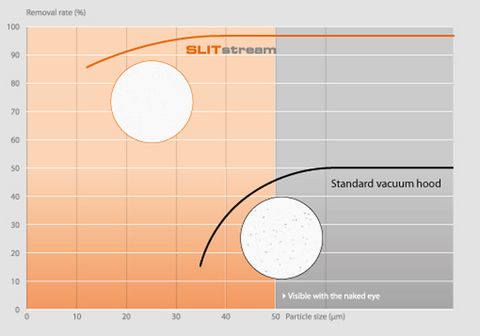

The special SLITstream technology effects that a flow of >30m/sec parallel to the knife forwards the sheet run direction is generated. Especially for this we have developed an air duct in the hood along the knife. This air flow guaranties, that >95% of loose particles >30µm will be efficiently removed already during the slitting process at the knife.