System Description

The iONcharge 4.0 is the latest generation of electrostatic charging electrodes in the manufacturing industry. The integrated high-voltage module allows perfect substrate charging without charge losses due to external high-voltage cables. The charging electrodes can easily be supplied by an external 24 VDC voltage. The efficient high-voltage decoupling via individual resistors at the tungsten emitter tips enables uniform high-voltage distribution over the entire working range and offers maximum efficiency with maximum service life. The level of the charging voltage can be controlled directly at the electrode itself or via the CAN bus connection. The iONcontrol Touch Panel controls several charging electrodes in a network.

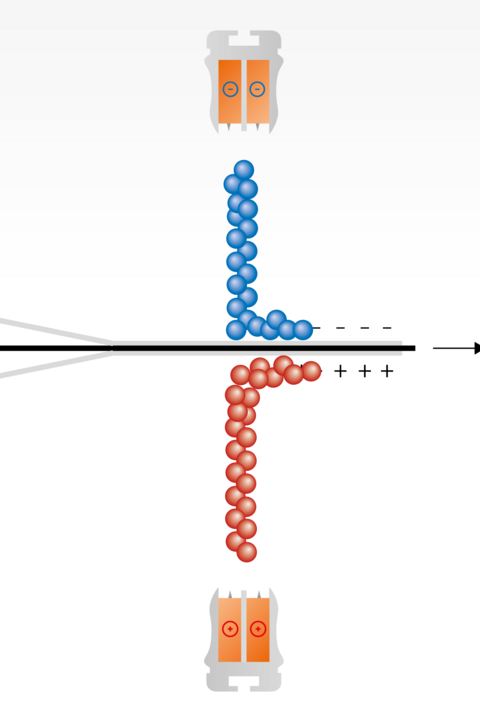

- iONcharge 4.0 electrodes available for positive (+20kV) and negative (-20kV) charging

- Integrated high voltage cascade

- High-quality tungsten emitter tips for long service life

- Uniform charging voltage over the entire working range due to resistance decoupling of the emitter tips

- High voltage adjustment on the electrode or via CAN bus connection

- External 24 VDC power supply

- Control of compound solutions via Can-Bus and iONcontrol Touch Panel

- Touch-safe charging electrodes

- All versions also available as EX versions

Applications iONcharge 4.0

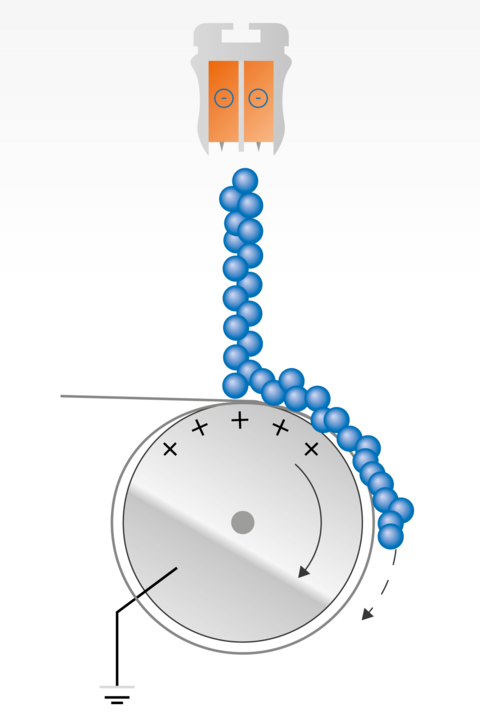

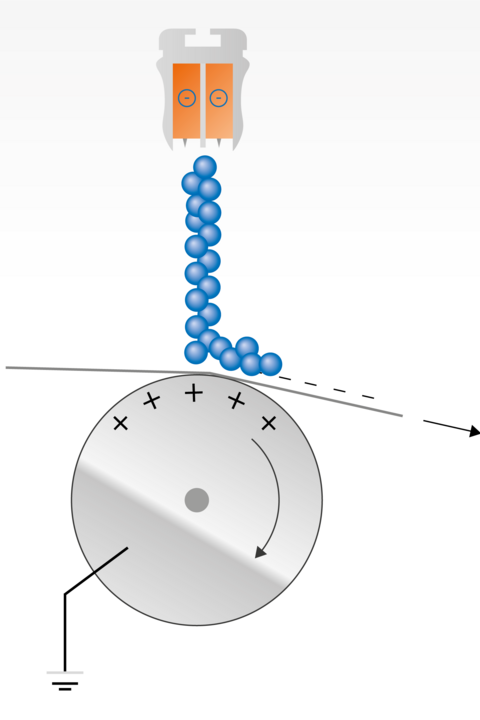

With the iONcharge 4.0 charging system, it is possible to automate and control a wide range of industrial processes through targeted charging. This includes fully automatic roll changes without gluing, blocking and adhesion of materials, improvement of print quality, targeted application of aerosols and coatings, fixation of web materials and much more. As an example, a positive or negative charging electrode is used for the blocking process depending on the substrate and requirement. The charging electrode provides the desired high voltage with the most homogeneous charge distribution over the entire working area. The substrates are perfectly blocked and ready for the next processing steps.