The appearance of electrostatic charge

The phenomena of electrostatic charge is permanent existing and is generated mainly by relative movement - in other words every time material surfaces have contact and are separated or have friction to each other. Static electricity in a working environment can for example be generated by fluids flowing through isolated pipelines or by production of endless insulated substrates (i.e. film and paper webs) moving through machines, or by granulates slipping over isolated surfaces, and even by a person walking on an isolated carpet.

The physics behind the phenomena

The electrostatics deals with quiescent electric loads, load distributions and the electric fields of loaded objects. Already in the antiquity it was known that certain materials draw small light particles, e.g., paper scrap, (frictional electricity) after the grating. The Greek word "elektron" for amber with which this phenomenon is to be seen good is the name giver for many areas of natural sciences.

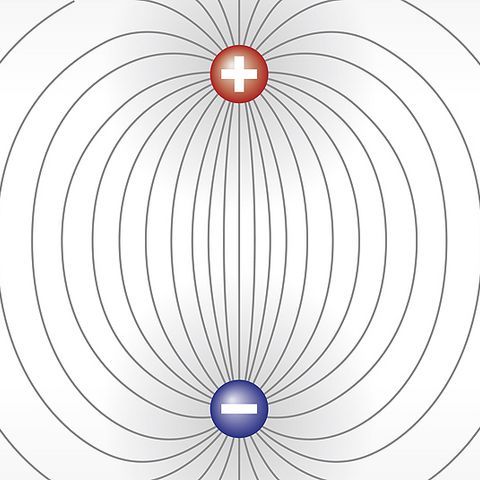

The phenomena of electrostatic is driven by the force which electrostatic fields generate to each other. These forces are described by the coulomb law. Even if the forces in the above example where paper snippets are attracted by a CD-ROM might look very small, the electrostatic force is in comparison with the gravitational force extremely strong. The force between an Electron and a Proton (both are building a hydrogen atom) is approximately 40 times bigger in comparison to the gravitational force between the both.

An impressive result of electrostatic charge built up caused by friction are thunder storm lightning's. The air is normally an isolator but with heavy electrostatic charges a breakdown can take place. In a flash of lightning abrupt equalization of charge between clouds, and in rarer cases between the clouds and the ground can appear.

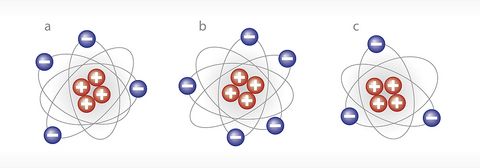

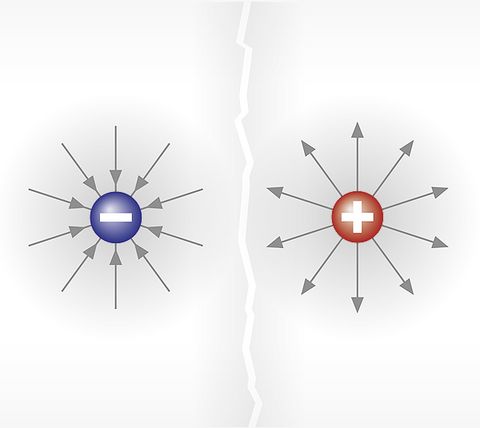

Every corpus, every object, but also fluids and all gases exist out of atoms and composed molecules. The atoms themselves exist out of positive charged Protons and negative charged Electrons. Important to the outside world is the relation, respectively the internal numeric count of both charges:

- Number of electrons = number of Protons = electrical neutral

- Number of electrons > number of Protons = electrical negative

- Number of electrons < number of Protons = electrical positive

Risk and damage caused by electrostatic charges

Damage to persons caused by startle response to sudden electrostatic discharges is a major cause for accidents in the industry. Explosive vapours, gases and dusts can also (under special circumstances) be ignited because the minimum ignition energy (MIE) can easily be exceeded. Isolated film surfaces can catch irreparable damages. Attraction or accumulation of unwanted particles can take place. Undesirable influence to coating processes, damage of semiconductor circuit's and machine PLCs, Displays and 24 V DC or 5 V DC Signal transmitters can also appear.

Factors of main influence

The amount and the polarity for the charge are driven by:

- The material itself

- Environmental situation (Temperature, humidity)

- Surface structure (roughness)

- Ongoing contact and separation of the substrates (i.e. unwinding, banana roller

- Speed of the web during separation - the higher the speed the higher is the corresponding charge on the substrate

Further more from:

- Distortion

- Cooling / crystallisation

- Friction / aerial currents in isolated surfaces

- Demolition / separation

Efficient control and elimination

In the first steps the following measures are mandatory:

- Detection of dangerous areas and critical processes where electrostatic charge can develop.

- Construction of an electrostatic profile of the critical areas or processes focused on operator safety, process problems and eventually material damages or surface changes based on electrostatic field measurements at the most dominate points in process with final risk assessment.

- Correct ground connection of conductive machine parts, work out the correct positioning of active Ionisation equipment in the machine and connect to Master control of the machine to have long time control over safety and the process.

- Use electrostatic training for operator and process engineers in regular intervals too insure up to date information for hazardous locations and critical process.

For pointed elimination of electrostatic charges the following action can be taken:

a) Use of grounded, passive eliminators close to the high charge. Passive eliminator can reduce the high charge effective but can never reduce the charge down to zero.

b) Radioactive Ionisation can also be used, but the circumstances of that equipment do to safety regulations are reduced to very low number of applications.

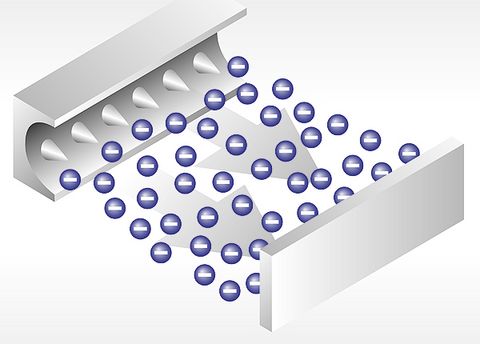

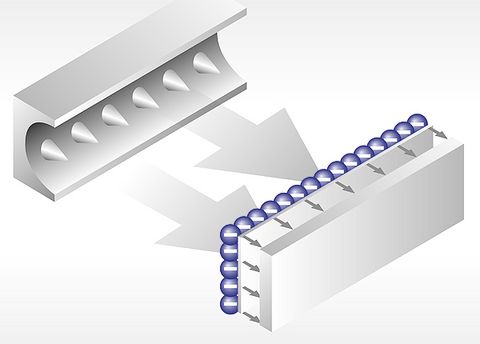

c) Active Ionisation: Ionisation bars with sharp pins connected to a high voltage generator ionise the air between the substrate and the bar and go into a neutralising relation between the two. In optimum position of the bar the charge can controlled down to zero (in difference to a passive assembly) even at high speed applications.

The use of Electrostatic charging

On the other hand, many critical processes in the industry can be solved by the use of electrostatic charge at the right point of use i.e. for automatic reel changeover of substrates without glue, blocking of or fixing of materials, improvement of printing quality, aimed transfer of aerosols or powders for coatings, reduction of machine downtimes, reduction of energy for the process (reduce use of vacuum generators) fixation of webs an many other application like this.

The pointed use of electrostatic charging can be achieved with different charging methods:

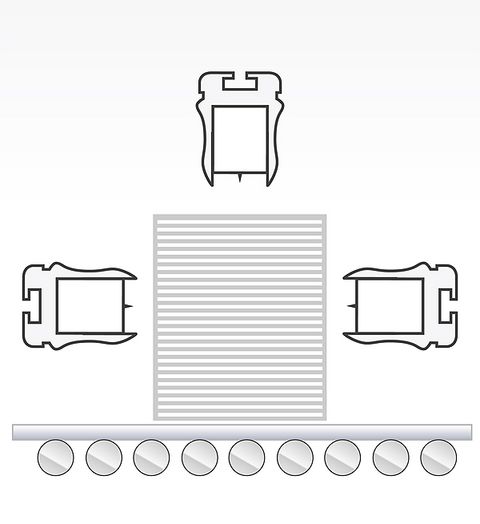

- Positive or negative charging of substrate against ground (i.e. grounded machine metal parts).

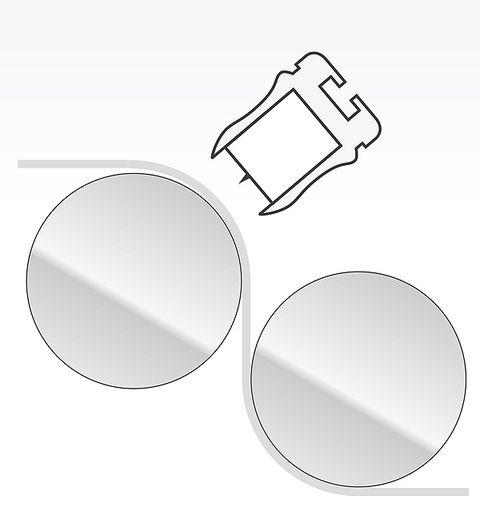

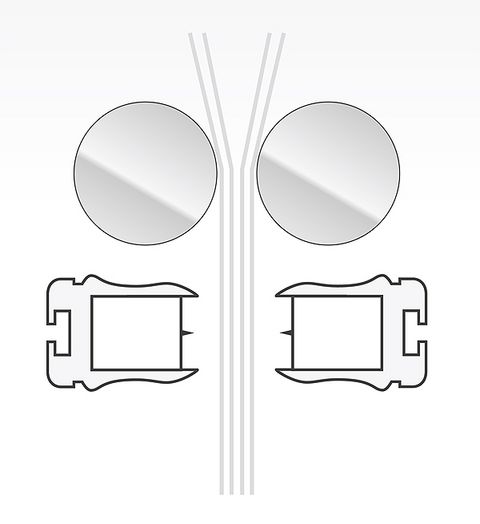

- Opposite positive and negative arranged charging bars to fixing or blocking 2 or more layers of isolating substrates.

- Charging of particles or aerosols in the electrostatic field against ground or opposite positive / negative arrangement.

Conclusion

Hildebrand Technology offers a number of electrostatic solutions for charging and antistatic applications. Every solution has some critical parameters which need to clarify before a decision is taken.

Which amount of charge is to be eliminated or supplied?

What is the maximum web speed?

What is the maximum expected residual charge?

What hazardous locations are we dealing with?

What is the planed Budget?

With above actions we can find together the best solution with the best Electrostatic Technology, where efficiency is high enough to solve the problem and stay inside the budget through reduction of waste material and machine downtime.

Our Engineers are ready to assist you in finding the best solution!